Last updated 4/7/20

If Siser Easyweed is giving you trouble, this blog can help you work through some basic troubleshooting techniques. Listed below are various different areas for troubleshooting Easyweed. This is a great resource for both beginners and seasoned experts. We will cover both cutting and pressing tips.

** Please note that this blog refers to normal Siser Easyweed only. Fluorescents, Stretch, and Extra have different application instructions**

Cutting

Double Check

- Cut Direction - cut in reverse (mirror image)

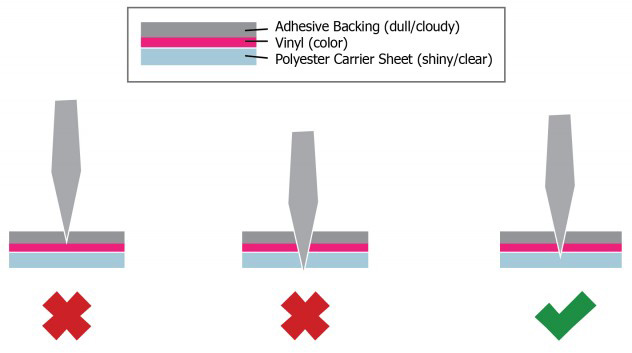

- Cut on the dull side of the material

Test Cuts

TEST CUT, TEST CUT, TEST CUT!! With any product, you need to do TEST CUTS before cutting your final design. Make sure you are cutting with the correct amount of force. When the proper amount of force is used, the material weeds much easier. Test cuts should be made for each color and for each product because each individual piece of vinyl can handle a little differently. Even if you have cut Easyweed before, different batches from the manufacturer can have a little variation. No batch, even if from the same manufacturer, is necessarily exactly the same. You can find recommended cut settings in the application instructions tab on our website, however these are a jumping off point and your cutter may still require some adjustment.

Invisible Cut Lines

Cut lines can be harder to see when cutting on colors such as white or yellow. Try holding the freshly cut sheet up to the light or place it on a light table to see if you can notice any cut lines. If you still don’t see anything, you should try adjusting the pressure to cut a little deeper into the material.

Difficult Weeding

When weeding, if the Easyweed is sticking and pulling up the design, then the cut is not deep enough on the material. You will then need to increase your cutting pressure to correct this issue. If it is not necessarily pulling up the design but still difficult to weed, you may have cut too deep. This will push the edges of the cut vinyl down into the liner making it more difficult to weed. Adjust your force with a test cut.

Pressing

Double Check

- Materials - Cotton, polyester, and poly/cotton blends

- Heat Press Temperature - 305 degrees Fahrenheit

- Pressing Time - 10 to 15 seconds

- Pressing Pressure - Medium pressure

- Peel - Hot or Cold

Can I Layer?

You can layer all colors of Easyweed! When layering, Easyweed boasts a "1 second tack" application. Press your first layer and each consecutive layer for 1-3 seconds. When pressing the final layer, press it for the full 15 seconds.

Transfer Not Sticking to the Garment

If Easyweed is heat pressed too long or pressed at too high of heat it will not stick to the garment. When too much pressing happens on a design, it is almost as if the adhesive gets completely burned off. On the other hand, if Easyweed is not pressed long enough or at too low of heat, it will also not stick to the garment. When too little pressing occurs, the adhesive backing doesn’t fully melt to adhere with the garment.

If all pressing instructions are followed and the Easyweed still doesn’t adhere to the garment, the material may need to be peeled cold. Peeling cold can allow the adhesive layer to fully set up and grip the garment.

Tips to Help Stick:

Some garments come with a slight coating to protect it from spills. Because of this thin layer, it can make it difficult for adhesives from any heat transfer vinyls to penetrate the garment. To weaken this thin protective coating on the garment, you can try a couple things.

- Dampen a cloth with rubbing alcohol (isopropyl alcohol), then gently apply it to the area on the garment you want to apply your design. Allow it to dry and apply your material.

- We highly recommend that you wash and dry your garments prior to pressing your design.

Is pre-pressing necessary?

Pre-pressing a garment when applying Easyweed isn’t super important. But, if you pre-press a garment, it can help get out wrinkles and smooth the application surface to help get an evenly pressed transfer. Pre-pressing also warms up the lower platen to give you all around heat when applying your graphic.

Please check out our Easyweed Tutorial video for more information.