What Are They?

Heat press pillows — soft foam pads, usually wrapped in a non-stick cover, designed to sit inside or under your garment during pressing. They come in different shapes/sizes to fit sleeves, hoodies, youth shirts, pants, etc.

Teflon sheets (aka PTFE / non-stick sheets) — thin, heat-resistant, non-stick covers that go above your design before you press. They protect both your garment and your heat press platen from adhesive, ink, or vinyl residue, and help produce a clean finish.

Platen Covers - much like the sheets, but they stay on your heat press machine— thin, heat-resistant, non-stick covers that go cover and protect your platens. They protect both your garment and your heat press platen from adhesive, ink, or vinyl residue, and help produce a clean finish.

Kraft Paper - a similar product, slightly less expensive but most sheets can only be re-used a few times. This is a great product for sublimation.

Why Use Them — What Problems They Help Solve

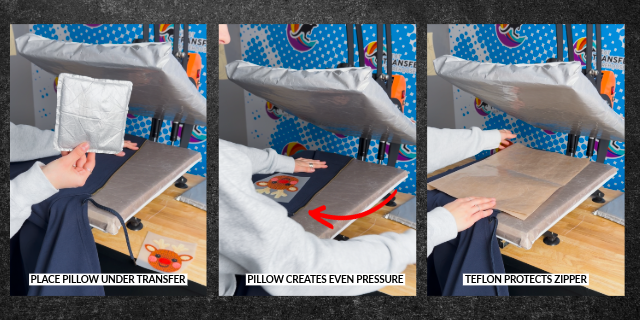

- Seams, Buttons, Zippers & Bulk: When pressing over thick seams, buttons, zippers, or heavy fabrics, a pillow raises the print area so pressure and heat hit your Heat Transfer Vinyl or DTF Transfer evenly — preventing missed adhesion or impressions.

- Even Pressure & Adhesion: A pillow helps distribute pressure evenly even if the fabric surface is uneven or layered. That leads to better adhesion of transfers, vinyl or HTV.

- Protecting Fabric & Press: The Teflon sheet acts as a protective barrier — stopping vinyl adhesive, ink, or residue from sticking to your machine, and protecting delicate fabrics or prints from scorching or sticking.

- Reusable & Cost-effective: Both pillows and Teflon sheets are durable, reusable tools — a small investment that improves consistency and longevity of your heat-press setup.

When to Use What — Examples

- Hoodie sleeves, pant legs, jackets, or any item with bulk, seams, or curves:

Use a heat press pillow underneath to raise the garment and achieve even pressure. - Shirts, hoodies, or items with smooth, flat surfaces (standard HTV transfers):

A pillow may not be necessary, but a Teflon sheet on top is still recommended for protection and a clean finish. - Layered vinyl, sublimation prints, or delicate fabrics:

Always use a Teflon sheet to prevent scorching, residue transfer, or uneven heat exposure. - Projects with seams, zippers, buttons, or pockets:

Combine a press pillow underneath with a Teflon sheet on top for smooth, even application and consistent results.

Quick How-To: Setup & Pressing Tips

- Insert the heat press pillow inside the garment (e.g., inside a sleeve or body) so that the area to be pressed lies smoothly over it.

- Center your HTV (Heat Transfer Vinyl) or design as usual.

- Lay the Teflon sheet over the design (between the upper platen and the garment) to act as a non-stick protective barrier.

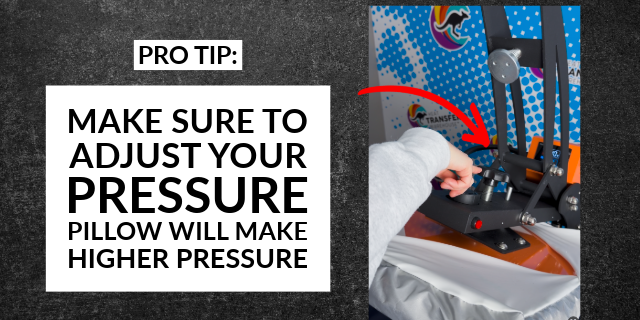

- Adjust pressure slightly if using a pillow — because the extra thickness may require slight pressure adjustment. It’s a good idea to test-press first.

- Press according to your vinyl/fabric’s recommended temperature/time. After pressing, remove sheet — vinyl should be neatly adhered; pillow can be removed and reused.

Final Thoughts

If you want clean, consistent, professional-looking heat-transfer results, using heat press pillows and Teflon sheets should be a standard part of your workflow. They’re especially helpful for tricky garments with seams, zippers, or bulky fabric. Once you get into the habit, you’ll notice the difference — fewer ruined jobs, better adhesion, and longer life for both your garments and press.