Materials Used

For the making of this creation, we used our new Hotmark Revolution in white.

Advantages of Hotmark Revolution:

- It's the first universal heat transferable vinyl (htv) that adheres to cotton, polyester, poly and cotton blends, nylon, and acrylics

- Is soft and flexible

- Works well with cutting and weeding small, intricate designs

- Offers quick application, low temperature pressing, and hot or cold peel

- Very easy to weed

- Can layer

The shower curtain that we used in this creation is a simple outter-layer 100% polyester curtain. However, this curtain is 100% waterproof, meaning that it is a coated polyester. Not all htv's will adhere to coated polyester. That's why we chose to use Hotmark Revolution -- this universal vinyl worked exceptionally well on the shower curtain.

Steps

The steps to applying Hotmark Revolution to a shower curtain (using a heat press) are basically the same steps you would follow in applying the vinyl to any garment. However, we did make a few adjustments to the pressing time.

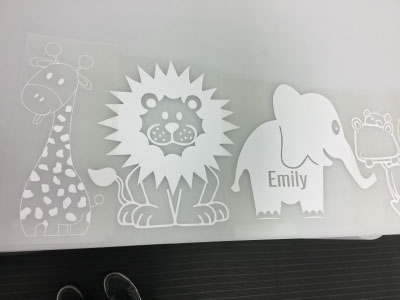

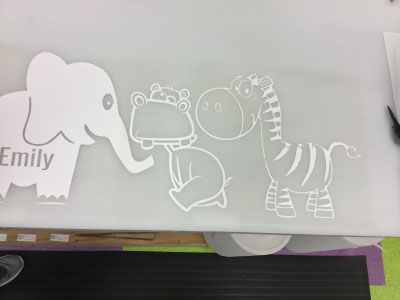

1) As always, create your unique artwork in vector form. Once your artwork is ready, send it to the cutter! In your cutter software, make sure to format the artwork in Reverse.

2) Cut your design given the appropriate material cut directions. The cut settings for our products using a Silhouette Cameo and a Graphtec CE6000 are listed on our website. We used Graphtec CE6000 with the cut force set at 16 for Hotmark Revolution. We recommend using a 45 degree blade when cutting this.

3) Once you have all of your design(s) cut, weed the excess material away from the liner.

4) Place your design(s) in the desired position on your shower curtain. Because this shower curtain had a waterproof coating over its polyester composition, we pressed pressed it at 230 degrees for 5 seconds, 7 seconds for designs with greater surface area (such as the lion and elephant).

- *Note that our website lists pressing times for much longer than this. The application insructions on our website does not account for coated polyesters, as the pressing time for different kinds of coated materials will vary.*

- ** We found that a damp a cloth with rubbing alcohol (isopropyl alcohol) was not needed here. We still recommned using rubbing alcohol when applying to other coated materials.**

Here is our final product! Try it out yourself and show us how it turns out!